You Are Here:Home > Information dynamic

> Industry Trends

News Navigation

What issues should be noted during the processing of formaldehyde free ENF grade environmentally fri

source:m.gq31.cn Time:2025-09-29

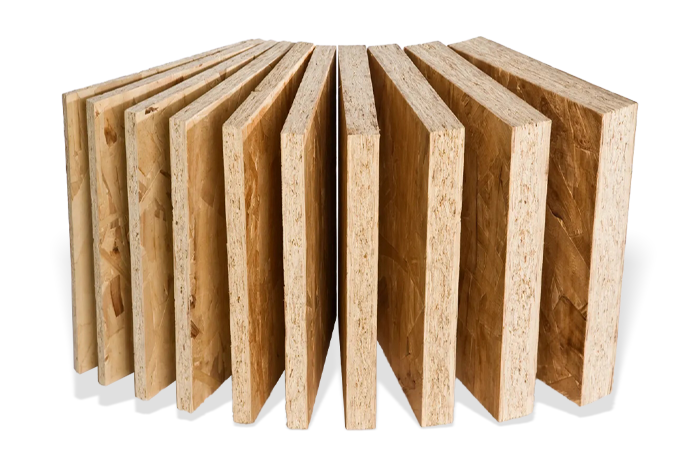

The processing of formaldehyde free ENF grade environmentally friendly particleboard should focus on the adaptation of adhesive properties, avoiding structural damage, and maintaining environmental performance, while also taking into account the differences in its physical properties from ordinary particleboard, to ensure that the quality of the processed product does not compromise with environmental standards.

1. Adapt adhesive properties to avoid processing failure

Formaldehyde free ENF grade particleboard often uses MDI adhesive or bio based adhesive, and the curing characteristics of these adhesives are different from traditional urea formaldehyde adhesives, requiring targeted adjustments during processing.

Control the hot processing temperature: MDI adhesive has strong high temperature resistance after curing, but during processing (such as edge sealing and hot pressing veneers), it is necessary to avoid local high temperatures (recommended ≤ 180 ℃) to prevent resin carbonization on the surface of the board, which affects the appearance and nail holding strength.

Choose compatible edge banding adhesive: When edge banding, it is necessary to use edge banding adhesive with strong compatibility with MDI adhesive (such as polyurethane edge banding adhesive), avoid using traditional EVA adhesive, prevent the edge banding strip from falling off due to incompatible adhesive layers, and ensure that the edge banding adhesive itself is formaldehyde free and does not damage the environmental properties of the board.

Adjust the cold pressing time: If cold pressing processing is carried out (such as multi-layer board composite), the cold pressing time needs to be extended (recommended to be 20% -30% longer than ordinary particleboard), because the curing speed of formaldehyde free adhesive is relatively slow, sufficient time can ensure complete adhesion of the adhesive layer and avoid cracking in the later stage.

2. Protect the sheet structure and reduce processing losses

Formaldehyde free ENF grade particleboard usually has a more uniform density, but its impact resistance differs from solid wood, so structural damage should be avoided during processing.

Optimize cutting parameters: Sharp alloy saw blades (recommended to have ≥ 80 teeth) should be used during cutting to reduce cutting speed (10% -15% slower than ordinary particleboard) and prevent edge breakage and fuzzing caused by excessive cutting stress, which may affect the subsequent edge sealing effect.

Control drilling depth and force: When drilling, adjust the drill bit speed according to the thickness of the board (it is recommended to drill at low speed for thin boards) to avoid the drill bit penetrating the board too deeply and causing cracking on the back; Simultaneously use positioning fixtures to fix the board, prevent board displacement during drilling, and ensure hole accuracy.

Avoid excessive polishing: When polishing the surface, use fine sandpaper (recommended 400 grit or more) and use a light pressure slow polishing method to avoid damaging the dense layer of the board surface due to excessive polishing, which may expose internal shavings and affect the adhesion and moisture resistance of the finish.

3. Maintain environmental performance and avoid secondary pollution

If aldehyde containing materials or processes are introduced during the processing, it will violate the ENF environmental standards, and the auxiliary materials and processes need to be strictly controlled.

Select formaldehyde free auxiliary materials: Use formaldehyde free auxiliary materials throughout the process, including edge banding (in compliance with ENF environmental standards), putty (water-based formaldehyde free putty), and coating (water-based formaldehyde free coating), to avoid excessive formaldehyde release in the finished product due to the presence of formaldehyde in the auxiliary materials.

Control the processing environment: The processing workshop needs to maintain ventilation to reduce dust accumulation; At the same time, avoid mixing the board with aldehyde containing materials (such as ordinary density board, urea formaldehyde adhesive) to prevent cross contamination.

Avoiding the risk of high-temperature decomposition: Although formaldehyde free adhesive is stable, long-term processing in high temperature (such as>200 ℃) or high humidity environments may result in the release of trace volatile substances inside the board. It is necessary to control the temperature and humidity of the processing environment (temperature 15-25 ℃, humidity 40% -60%).

4. Adapt to physical characteristics to improve machining accuracy

Due to differences in raw materials and processes, the physical properties (such as nail holding force and moisture content) of formaldehyde free ENF grade particleboard are different from those of ordinary particleboard, and the processing technology needs to be adjusted accordingly.

Control moisture content: Before processing, the moisture content of the board should be tested (recommended to be controlled at 8% -12%). If the moisture content is too high, it should be dried first to avoid deformation and cracking of the finished product due to moisture evaporation and shrinkage of the board after processing; If the moisture content is too low, it is necessary to humidify it appropriately to prevent the board from becoming brittle and affecting the nail holding force.

Adjusting the nail holding process: Its nail holding force is usually better than that of ordinary particleboard, but when screwing nails on the edge or thin plate of the board, it is necessary to pre drill guide holes (with a diameter of 70% -80% of the screw diameter) to avoid edge splitting caused by direct screwing. At the same time, coarse tooth screws are selected to improve nail holding stability.

Adaptation of veneer technology: When veneering (such as melamine paper, wood veneer), the hot pressing pressure should be adjusted according to the surface flatness of the board (recommended 0.8-1.2MPa). If the pressure is too high, it will cause uneven density of the board, and if the pressure is too low, it will cause the veneer to not fit tightly, resulting in bubbles and curled edges.

1. Adapt adhesive properties to avoid processing failure

Formaldehyde free ENF grade particleboard often uses MDI adhesive or bio based adhesive, and the curing characteristics of these adhesives are different from traditional urea formaldehyde adhesives, requiring targeted adjustments during processing.

Control the hot processing temperature: MDI adhesive has strong high temperature resistance after curing, but during processing (such as edge sealing and hot pressing veneers), it is necessary to avoid local high temperatures (recommended ≤ 180 ℃) to prevent resin carbonization on the surface of the board, which affects the appearance and nail holding strength.

Choose compatible edge banding adhesive: When edge banding, it is necessary to use edge banding adhesive with strong compatibility with MDI adhesive (such as polyurethane edge banding adhesive), avoid using traditional EVA adhesive, prevent the edge banding strip from falling off due to incompatible adhesive layers, and ensure that the edge banding adhesive itself is formaldehyde free and does not damage the environmental properties of the board.

Adjust the cold pressing time: If cold pressing processing is carried out (such as multi-layer board composite), the cold pressing time needs to be extended (recommended to be 20% -30% longer than ordinary particleboard), because the curing speed of formaldehyde free adhesive is relatively slow, sufficient time can ensure complete adhesion of the adhesive layer and avoid cracking in the later stage.

2. Protect the sheet structure and reduce processing losses

Formaldehyde free ENF grade particleboard usually has a more uniform density, but its impact resistance differs from solid wood, so structural damage should be avoided during processing.

Optimize cutting parameters: Sharp alloy saw blades (recommended to have ≥ 80 teeth) should be used during cutting to reduce cutting speed (10% -15% slower than ordinary particleboard) and prevent edge breakage and fuzzing caused by excessive cutting stress, which may affect the subsequent edge sealing effect.

Control drilling depth and force: When drilling, adjust the drill bit speed according to the thickness of the board (it is recommended to drill at low speed for thin boards) to avoid the drill bit penetrating the board too deeply and causing cracking on the back; Simultaneously use positioning fixtures to fix the board, prevent board displacement during drilling, and ensure hole accuracy.

Avoid excessive polishing: When polishing the surface, use fine sandpaper (recommended 400 grit or more) and use a light pressure slow polishing method to avoid damaging the dense layer of the board surface due to excessive polishing, which may expose internal shavings and affect the adhesion and moisture resistance of the finish.

3. Maintain environmental performance and avoid secondary pollution

If aldehyde containing materials or processes are introduced during the processing, it will violate the ENF environmental standards, and the auxiliary materials and processes need to be strictly controlled.

Select formaldehyde free auxiliary materials: Use formaldehyde free auxiliary materials throughout the process, including edge banding (in compliance with ENF environmental standards), putty (water-based formaldehyde free putty), and coating (water-based formaldehyde free coating), to avoid excessive formaldehyde release in the finished product due to the presence of formaldehyde in the auxiliary materials.

Control the processing environment: The processing workshop needs to maintain ventilation to reduce dust accumulation; At the same time, avoid mixing the board with aldehyde containing materials (such as ordinary density board, urea formaldehyde adhesive) to prevent cross contamination.

Avoiding the risk of high-temperature decomposition: Although formaldehyde free adhesive is stable, long-term processing in high temperature (such as>200 ℃) or high humidity environments may result in the release of trace volatile substances inside the board. It is necessary to control the temperature and humidity of the processing environment (temperature 15-25 ℃, humidity 40% -60%).

4. Adapt to physical characteristics to improve machining accuracy

Due to differences in raw materials and processes, the physical properties (such as nail holding force and moisture content) of formaldehyde free ENF grade particleboard are different from those of ordinary particleboard, and the processing technology needs to be adjusted accordingly.

Control moisture content: Before processing, the moisture content of the board should be tested (recommended to be controlled at 8% -12%). If the moisture content is too high, it should be dried first to avoid deformation and cracking of the finished product due to moisture evaporation and shrinkage of the board after processing; If the moisture content is too low, it is necessary to humidify it appropriately to prevent the board from becoming brittle and affecting the nail holding force.

Adjusting the nail holding process: Its nail holding force is usually better than that of ordinary particleboard, but when screwing nails on the edge or thin plate of the board, it is necessary to pre drill guide holes (with a diameter of 70% -80% of the screw diameter) to avoid edge splitting caused by direct screwing. At the same time, coarse tooth screws are selected to improve nail holding stability.

Adaptation of veneer technology: When veneering (such as melamine paper, wood veneer), the hot pressing pressure should be adjusted according to the surface flatness of the board (recommended 0.8-1.2MPa). If the pressure is too high, it will cause uneven density of the board, and if the pressure is too low, it will cause the veneer to not fit tightly, resulting in bubbles and curled edges.

Previous:

Why should families with infants and young childr…

Next:

Why is odorless E0 grade environmentally friendly…

Related articles

+

wechat number:底部微信

Home

Home

Wechat

Wechat

Tell

Tell